In 2022, the classic car industry is booming like never before. Models like the Mercedes-Benz 300 SLR Uhlenhaut Coupé are breaking sales records, while events like the Goodwood Revival and Pebble Beach Concours d’Elegance are becoming more popular than ever. Yet, despite this surge of interest in the classic car world, a startling problem is emerging as experienced master mechanics and car restorers across the globe begin to retire without passing down their knowledge to the next generation.

Luckily, John and Janice Pitchforth recognised this issue, and established the Heritage Skills Academy in 2016 to promote and deliver classic vehicle apprenticeships in mechanical engineering and coachbuilding. The catalyst from the industry was Mark Hews, CKL’s Managing Director, who saw that the industry was thriving but very few new young engineers were aware of the exciting career opportunities it offered. Fast forward to 2022 and the Heritage Skills Academy now has two world-class academies based at Bicester Heritage and Brooklands Museum, 170 apprentices and 14 dedicated staff. When the apprentices aren't studying at the two academies, they get the chance to learn from some of the best in the industry at CKL. We headed down to CKL’s headquarters in East Sussex to speak to Mark and meet some of the Heritage Skills Academy apprentices who’ll be making sure your classic car keeps running for decades to come.

Upon entering the immaculate facility, we’re met by Chris Keith-Lucas, the company’s ever-welcoming founder, who offers some insight as to why the classic car industry is experiencing such a skill drain. “Somebody starting out now has to make a bigger jump than previous generations have. My generation put chains back on our bikes and mended punctures. I had carpentry tools from the age of six and chisels and saws and things I could cut my fingers off with, yet it was never considered a problem. Now kids have to make a much bigger leap because they don’t have the underlying exposure to tools from an early age. We are introducing much older people to this equipment, but thankfully some will take to them like a duck to water, which is great to see.”

Considering the calibre of automobiles that pass through CKL, you’d think a trainee apprentice wouldn’t be let within 100 metres of the facility, yet the reality is quite the opposite. Mark gives us the low-down: “We have five junior people out of a team of 18 at CKL who are apprentices. There’s a lot of people who are retiring - all the skills are found in people who are 60-plus years old. There’s a big skill gap between 25 and 45 in this industry.”

“Modern apprenticeships don’t have relevant coach building courses nowadays. I think there’s only one apprenticeship course teaching bodyshop skills in the country, which is just insane. Heritage Skills Academy’s coach building apprenticeship for classic cars will allow trainee’s to earn a big wage eventually. As the skilled workers start retiring, these skills are going to become more and more valuable,” Mark continues.

“The incentive is not just for these apprentice’s but there are huge benefits for the business as well. If I took on a mechanic from a Ferrari dealer for example, they wouldn’t be able to come in here and restore a Jaguar, so they wouldn’t be useful to me for six months, but I’d still be paying them a premium wage because they are a high level technician. On the other hand, I can get an apprentice and they’ll start earning the company money after a year because their wage is so much smaller. So, from a business perspective, we gain much more from taking on an apprentice and teaching them our way.”

“At CKL we probably have one of the youngest workforces in the industry. You look around, and there’s a lot of very experienced guys, but a large proportion of the team are in or below their mid 30’s, so we’re not worried about the future of our company, we’re interested in the future of this industry as a whole,” Mark concludes.

On that note, we head into CKL’s panel shop, to meet one of their youngest apprentices, Teo, who surprisingly wasn’t a petrolhead before working at CKL. “I wanted to learn a lot of different skills and ways of applying those skills. The fact that there’s metalwork, upholstery, mechanics, and woodwork gives you a broad understanding of how these cars go together. I didn’t start with a passion for cars, but it has certainly grown more and more while working here, and I definitely plan to continue in this industry after the apprenticeship,” says Teo.

Clearly the variety of challenges in CKL’s workshop is a huge draw for these young apprentices, as Mark explains, “We’re not a one-trick pony here, we are Jaguar specialists and we know a huge amount about Jaguars - we won’t move away from that, but it’s hard to reject a customer’s car, so we’re open to all sorts. There’s a broad range of things we do here, but the point of the apprenticeship is to teach the core skills. These skills can be used on a Jaguar, Ferrari, or Lamborghini. The same applies in the metal shop - whatever the skills are, they can transfer them between different cars.”

Of course, behind every great apprentice is a restoration wizard, and in Teo’s case, that man is John, who’s worked at CKL for over 20 years. Training the next generation is no small feat, as John tells us, “One of the most difficult things to teach is knocking out and restoring original panels while trying to retain as much of the original metal as possible. It requires a lot of research online and in our archives to know exactly what it was like in the day, not just how it may have been restored.” John shows us images of the Le Mans-winning C-Type that he helped to restore, and explains, “I need to know what it looked like and how they built them, so you can restore these cars with the same mindset.”

However, it’s not just youngsters who are jumping at the chance to experience an apprenticeship at CKL. Next up, we meet Jörn, a senior apprentice and ex-cultivation biologist who’s been gaining experience at CKL for the last 19 months. Jörn tells us why he decided to drop biology in pursuit of classic car restoration, “I’ve had a passion for classic cars my whole life, and I wanted to do something different and hands-on. I owned a Volvo Amazon for 12 years, so I’ve always been tinkering on that, but the cars I work on here are more valuable and exciting. They have to function properly as they’re going out racing, whereas my Volvo Amazon doesn’t.”

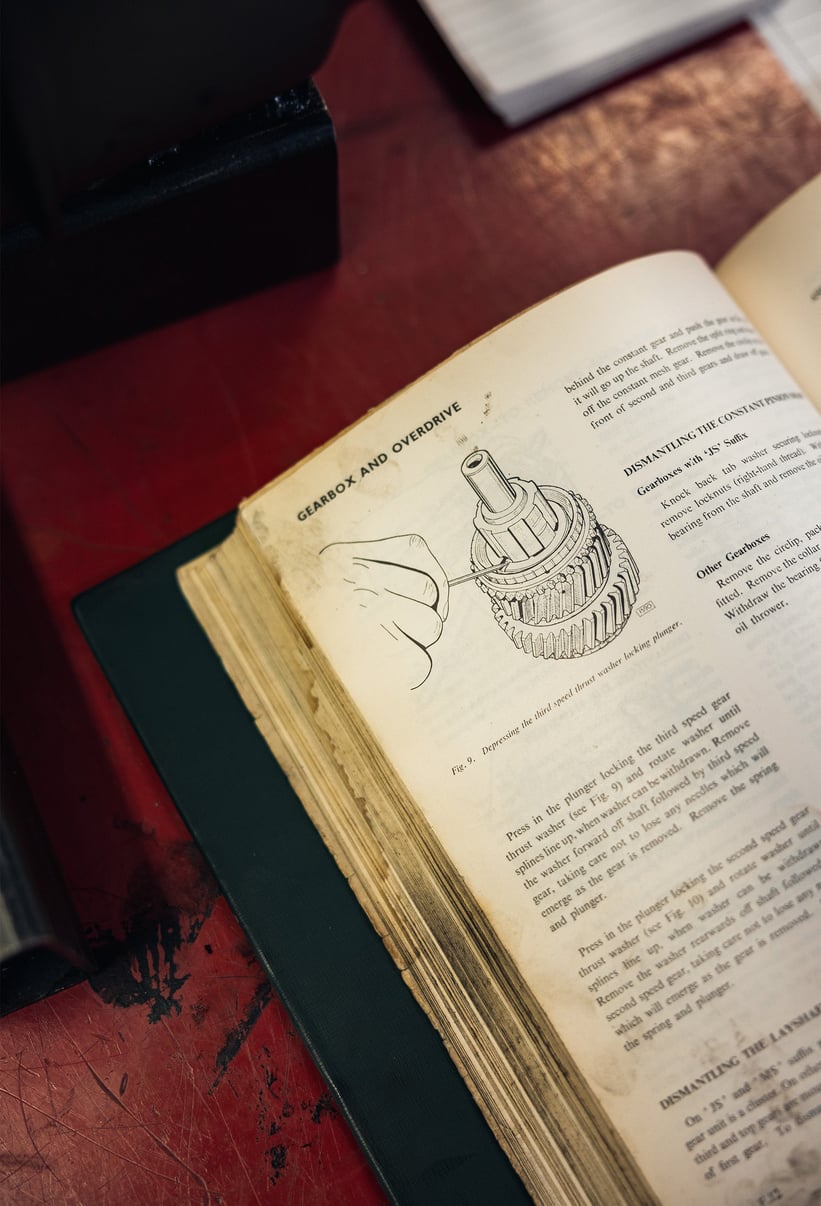

“I plan to finish this apprenticeship and see where it goes, but I hope to continue this afterwards, as it’s been good fun. The variety has been really exciting - one week you’re working on gearboxes and the next you’re working on engines. Electrics has been quite hard to get my head around, but when it works it’s really rewarding. I’ve worked on a huge number of cars in the 19 months I’ve been here, and I even did a little bit of work on the 1953 Le Mans-winning C-Type which was really incredible. You can see the development between the different D-Types we have in here at the moment; every race, Jaguar were modifying the cars to make them a little better, and that’s fascinating to see.”

Leaving Jörn to work on the overdrive-equipped Moss gearbox on his bench, we move over to one of our final victims, Bradey, who’s motivations for joining CKL are a bit closer to what we’d imagined at the start. “My family have always had an interest in cars - my nan had a Mk 9 Jaguar in the 60s and 70s, my dad has a Sunbeam Alpine, so I’ve always been around cars.”

“After Covid it was really difficult to get a job coming out of college. I found CKL and I got in touch with Mark, and I was just amazed at the facilities and the variety of cars in here. There’s machining, welding, painting, working on race cars and road cars - it was a real eye-opener and it’s a privilege to work here. I want to stay here once I finish my course. I’ve been here since July, so hopefully soon I’ll be able to level up to full-time mechanic.”

Bradey has been working closely with another of CKL’s veteran mechanics, Dave, who’s been with CKL since 2008. With so much experience under his belt, we had to ask Dave which skills were the hardest to teach: “You’re not just fitting parts, it’s old-school engineering. That’s what I like most about this job: it’s a bit more of a puzzle. Basic hand-tooling is one of the most difficult things to teach. In modern cars, if something doesn’t fit, you send it off and get a different part. Here, you have to start filing and make it work. We’re fabricators and mechanics, we’ll weld and do anything we can to get the project moving in the right direction. When you’re building a car you need to understand the whole picture, and if you don’t have that understanding and communication between the departments, you often end up going backwards.”

It’s Dave’s final point that really summarised our whole experience with CKL’s masters and apprentices; no matter their age, or what department they’re working in, the guys at CKL are teaching and learning from each other, which forms a cohesive team. Regardless of the potential for a healthy salary at the end of the apprenticeship, the bond between the guys in CKL’s workshop and their shared enthusiasm is the greatest incentive we can think of for young people looking to get involved in classic car restoration.

Photos by Tom Shaxson for Classic Driver